By selecting high quality materials and components, we are able to build safe, strong, and enjoyable boats.

-

•Construction is a layered build from gelcoat on the outside to final assembly, with a focus on quality control and teamwork.

-

•Key materials include no rot Coosa board, high density foam cores and fiberglass that strengthen the hull and help reduce weight.

-

•Quality is a continuous effort guided by Listen Lead Create, with every department collaborating from design to final assembly.

Sportsman Boats are made of thousands of separate components. Our specially crafted designs are carefully built and monitored to ensure the highest level of quality and satisfaction possible. Our team is proud of the work put into each boat and they are truly created through a team effort. We have put together a quick overview of our boats’ construction to help you understand what boats are made of. For additional information and details, please visit our website as well as our new series, Behind the Glass.

Boats are built from the outside in, starting with the outside layer. This outside layer is called gelcoat which is a pigmented layer of resin. Gelcoat is one single tough layer and is the color you see on a boat when it speeds by. The skincoat layer follows the gelcoat and is a big defense against water penetration. Sportsman Boats use a vinal ester resin, which is tough and resists blistering. To finish this layer, the team will use special rollers called “bubble rollers” which are small, spiked tubes, to remove any air that was trapped between the first and second layer. This prevents any air voids in the future.

The next step consists of various composite materials which are added to the construction. The hull sides receive a full layer of hi-density PVC foam coring. This is great for sound dampening and adding rigidity to the boat. To finish off the lamination process, bulk fiberglass pre-cut to each unique boat is hand laid. This step helps to ensure proper thickness across the hull. One of the most importance pieces of composite material is at the transom. This area feels the stress and weight of the boat’s engines. In this area, we use a no-rot composite material called Coosa board. It will never rot, mold, or mildew. These materials significantly strengthen the boat while providing better performance and reducing the overall weight. All our stringers are fully structural fiberglass parts that require no foam for rigidity.

Once the hull, deck, and stringer have properly cured, they are pulled from the mold and move onto the next step. The Stringer is affixed to the inside of the hull using a powerful epoxy called methyl methacrylate, an incredibly strong polymer used by NASA. The cavities of the stringer are then filled with foam to offer additional floatation as well as insulation.

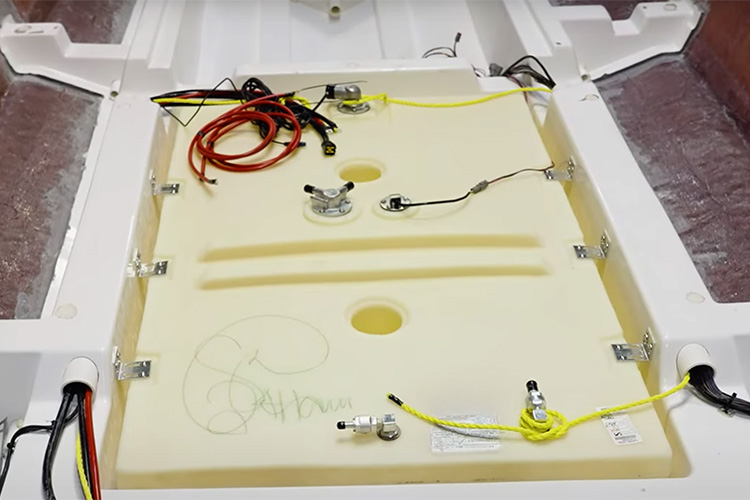

The assembly process is the combines the components of the boat and their installation. Every component has a designed-in spot and purpose. Before the deck and hull are combined, important elements are installed and placed. The gas tank is fit inside the stringer grid. Most of the fuel tanks are made out of a high-density polyethylene plastic. On our larger models, we use aluminum tanks. Then the wiring and electrical components are added. The bilge pump, underwater lights, and many additional build-specific parts are installed at this time.

Once all parts have been placed, the hull and deck move to the capping process. Sportsman Boats are joined using a polyester bonding putty that adheres the deck to the stringer. The deck is hoisted in the air, the hull is wheeled underneath it and they are married together. The deck and hull are finally pinned together using screws through the special composite materials to ensure screw retention at the pinning flange.

At this point in the boat building process, the vessel is starting to resemble a boat. Elements from our different departments are brought into the main production line and attached. This includes the console, T-top, seat frames, upholstery, electronics, and more. These separate parts are all installed by our incredible assembly team.

By selecting high quality materials and components, we are able to build safe, strong, and enjoyable boats.

For Sportsman Boats, building a great boat does not end when the boat leaves our plant. Quality is a continuous effort; we internally coined the term “Listen Lead Create”. This means we listen to our customers, lead the pack in innovation, and create the absolute best boat we can.”

For more information on How Sportsman Boats are made, check out our “Behind the Glass” series: https://www.sportsmanboatsmfg.com/series/1-behind-the-glass-season-1

Information pulled from the Behind the Glass Series, and the Sportsman Boats website.

Related Posts

Sportsman Boats answers the frequently asked questions including what the function of a stringer is and where boats get their strength.

Read More