Breaking down and comparing the two most commonly used batteries for marine applications; lead acid and AGM.

-

•AGM batteries are sealed which minimizes gassing and allows mounting in tight marine spaces in any orientation except completely upside down

-

•AGMs recover faster on charging and offer a higher depth of discharge about 80 percent versus 50 percent for lead acid

-

•Despite higher upfront cost AGMs typically last about seven years compared with three to five for lead acid

Today, in keeping with my previous battery switch blog, I will be discussing Lead Acid and AGM batteries. While there are other battery types on the market, these are the two most common.

Both Lead Acid and AGM are technically the same base chemistry; but their design and function are greatly different. A Lead Acid uses lead plates submerged in liquid electrolyte. AGM also uses lead plates submerged in electrolyte but has fiberglass mats sandwiched between them. This mat absorbs the electrolyte which results in virtually no gassing. This allows an AGM to be sealed and able to mount in any orientation, except completely upside down. Because a Lead Acid produces gasses, it has to be vented and can only be mounted right side up. The AGMs sealed design makes it ideal for tight locations often found in marine applications.

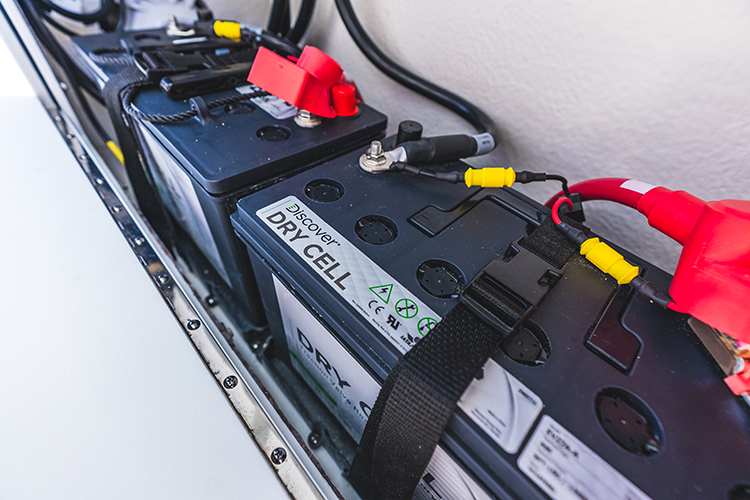

Discover AGM Batteries

Discover AGM BatteriesWhen it comes to durability, the AGM is once again superior. Thanks to the sandwiched glass mats, the lead plates are less likely to break loose from the constant vibration and pounding in a marine environment.

Lastly is the performance between the two. Because an AGM has a lower internal resistance, it has a faster recovery charging time. This is up to 5 times quicker than a Lead Acid while maintaining the same amount of discharge and using the same charger. The amount of Depth of Discharge is also greater for an AGM. This is the amount a battery can be run down without damaging results to the battery. An AGM has a 80% depth of charge versus 50% for a lead acid.

Discover AGM Batteries

Discover AGM BatteriesIn summary, my opinion is that an AGM is by far superior for marine applications than Lead Acid. Yes, AGMs are more expensive but the life expectancy is up to 7 years versus the 3-5, if you're lucky, from a Lead Acid. Additionally, I am aware of Gel and Lithium options, I will cover those in a later post, today was covering the two most common options for marine applications.

Tight Lines and safe boating!

Related Posts

Yamaha’s binnacle LED color customization lets boaters personalize their controls for both style and safety. With adjustable settings for ne...

Read More