Blog > Behind The Scenes: Printing the 2019 Product Catalog

On this special post, we are taking you behind the scenes to see the process of printing our catalog.

October 19, 2018

-

•The 2019 catalog production is a multi-step process from paper preparation to final assembly.

-

•Color accuracy is tightly controlled using Rotoman units and multiple color level adjustments to ensure the prints match the original design.

-

•Teamwork and multiple review cycles are essential to guarantee quality before the catalog moves to assembly.

Columbia, SC Take a look at these rare behind the scenes photographs of our team putting together the 2019 Product Catalog. A huge thank you to all of those involved in making this year's catalog that much better.

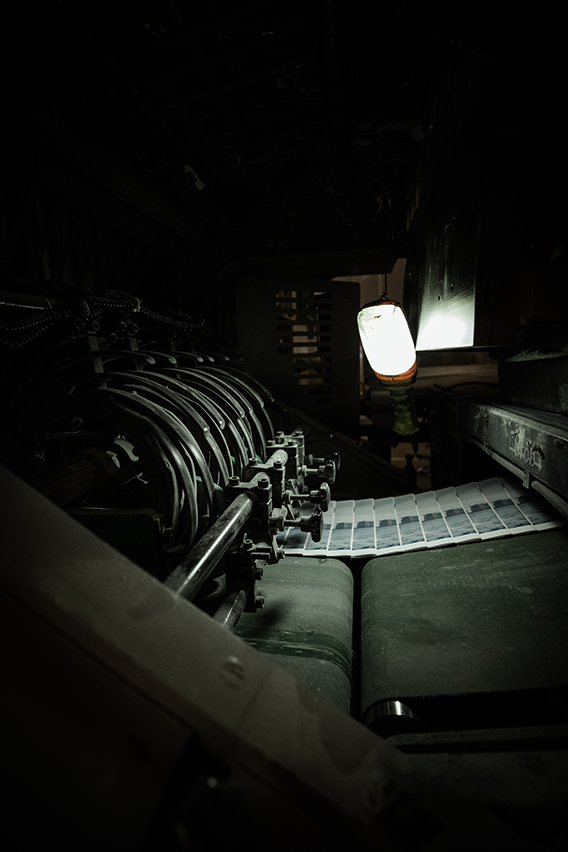

Here is where the paper reaches the end of the line and starts the stacking process.

Here is where the paper reaches the end of the line and starts the stacking process.

At this stage the paper is 100% dried and is heading towards the folding.

At this stage the paper is 100% dried and is heading towards the folding.

These buttons adjust color levels on the press.

These buttons adjust color levels on the press.

Here is where the paper gets folded for the first time.

Here is where the paper gets folded for the first time.

Here the paper getting folded then heading into the cutter and second folder.

Here the paper getting folded then heading into the cutter and second folder.

Here the paper is cut, folded, and heading towards stacking.

Here the paper is cut, folded, and heading towards stacking.

Here you can see stacks of the catalog being placed in bins to head to assembly.

Here you can see stacks of the catalog being placed in bins to head to assembly.

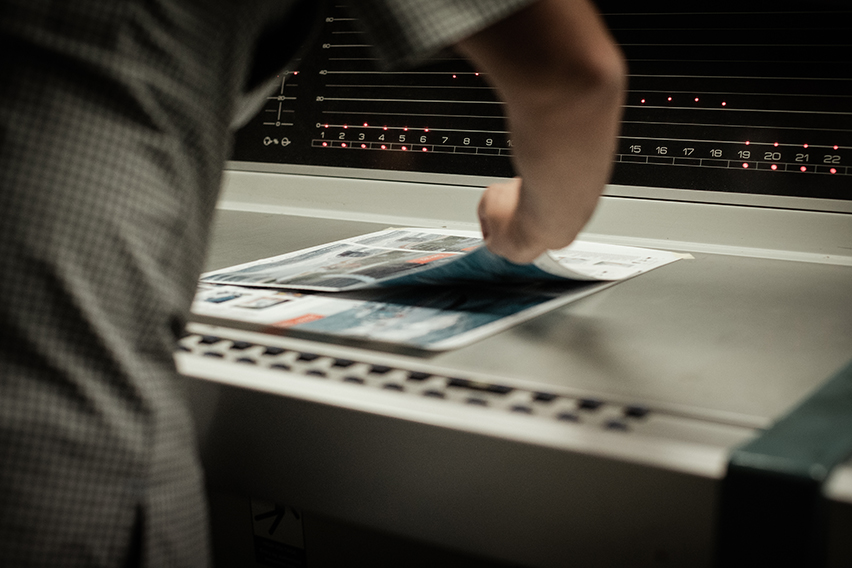

Machine techs evaluating color levels based off the original signature.

Machine techs evaluating color levels based off the original signature.

From the oven to the cooling rollers.

We spend hours reviewing and discussing final results.

We spend hours reviewing and discussing final results.

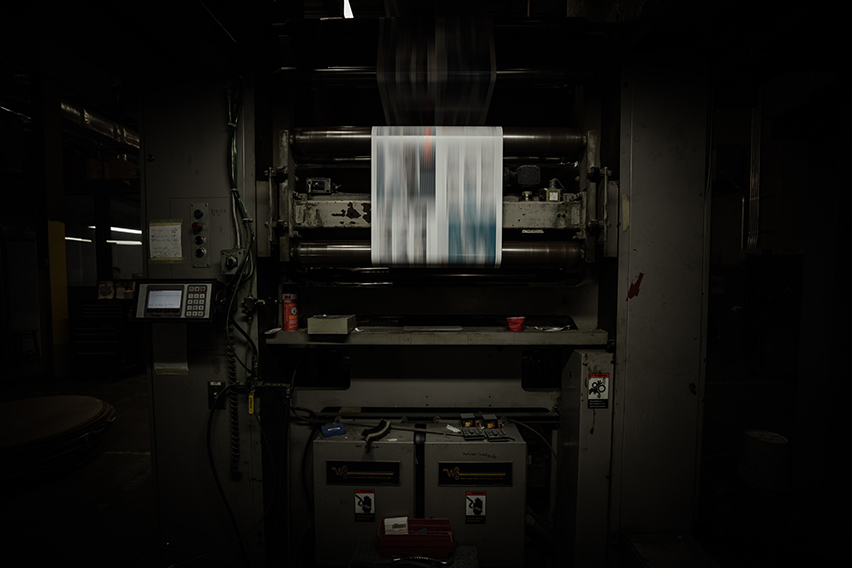

Here is the paper leaving the yellow rollers heading towards the oven.

Here is the paper leaving the yellow rollers heading towards the oven.

Each one of these Rotoman units houses a different color for the paper to pass through.

Each one of these Rotoman units houses a different color for the paper to pass through.

Each signature needs several review periods.

Each signature needs several review periods.

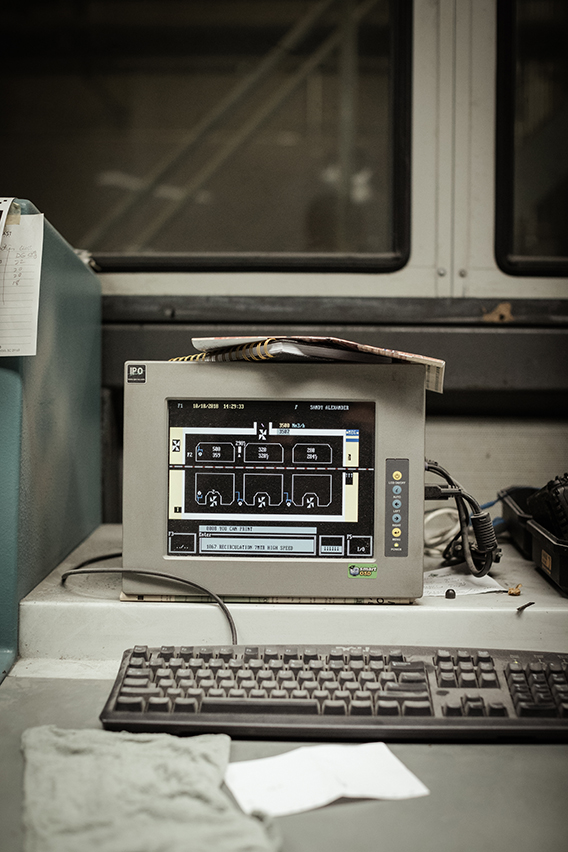

Here’s a display that shows each one of the Rotoman units and its color. Also, you can see sample count.

Here’s a display that shows each one of the Rotoman units and its color. Also, you can see sample count.

Here you can see the levels for each line of color. This is very important in the adjustment stages.

Here you can see the levels for each line of color. This is very important in the adjustment stages.

Victor comparing actual colors to the prints.

Victor comparing actual colors to the prints.

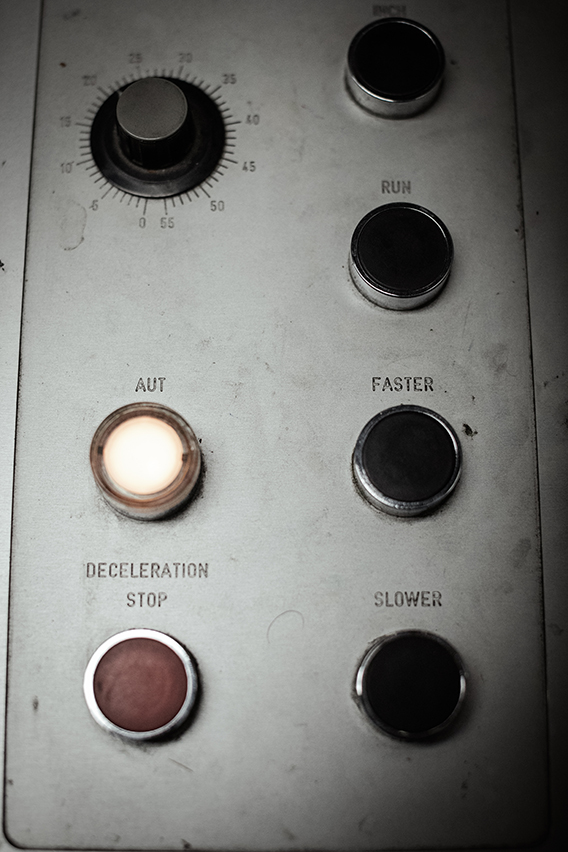

When all else fails just hit the FASTER button.

When all else fails just hit the FASTER button.

This monitor shows the temperatures of the 40ft long oven the paper goes through to allow for the ink to dry.

Here are the guys stacking copies at the end of the line.

Here are the guys stacking copies at the end of the line.

Massive rolls of paper. This machine is a beast to say the least!

Massive rolls of paper. This machine is a beast to say the least!

Related Posts

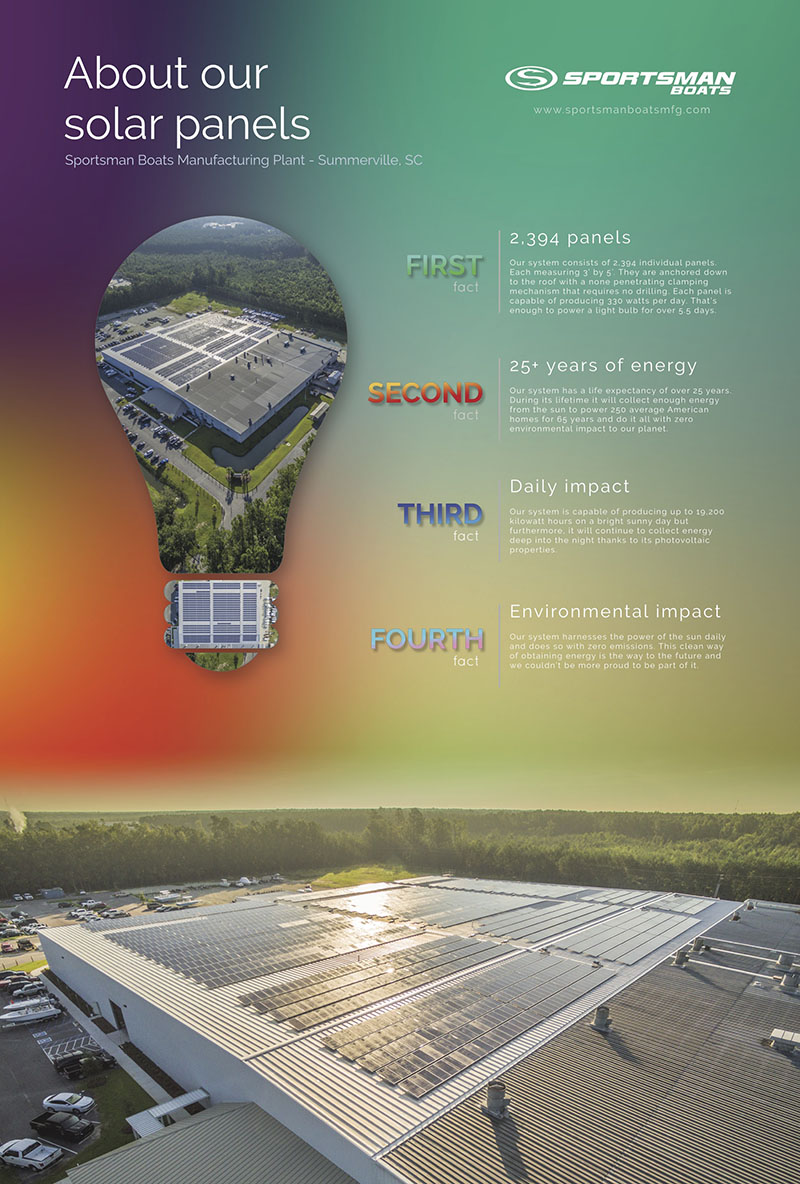

About our solar panels

August 24, 2017

A multi-million dollar solar panel project in Summerville, South Carolina

Read MoreSeries

Fishing 101 (9)

Heritage 321 (1)

Open 402 (2)

SportLink® (2)

SportTuun® (3)

Tech Talk (49)

Tide To Table (9)