How thick is the hull of a fiberglass boat?

Sportsman Boats answers the frequently asked questions including how thick the hull of a boat made of fiberglass is.

While every boat model has a differently thick hull side, we think it is important to learn what materials and process Sportsman Boats uses to build your hull.

The outside layer component of a boat is called gelcoat which is a pigmented layer of resin. Gelcoat is one single tough layer. This allows it to be sanded and buffed throughout its life to bring back the original finish.

Once the gelcoat has been sprayed on the mold, to ensure proper thickness and consistency, a quality technician takes measurements using a mill gauge. This is a small metal tool that allows our team to measure the thickness of the gelcoat. Proper thickness of gelcoat is key. Improper thickness can cause gelcoat to be translucent or brittle. The results are closely recorded using a tablet at each of the quality stations.

The skincoat layer follows the gelcoat and is a big defense against water penetration. Sportsman Boats use a vinal ester resin, which is tough and resists blistering. To finish this layer, the team will use special rollers called “bubble rollers” which are small, spiked tubes, to remove any air that was trapped between the first and second layer. This prevents any air voids in the future.

The next step consists of various composite materials which are added to the construction. The hull sides receive a full layer of hi-density PVC foam coring. This is great for sound dampening and adding rigidity to the boat. To finish off the lamination process, bulk fiberglass pre-cut to each unique boat is hand laid. This step helps to ensure proper thickness across the hull.

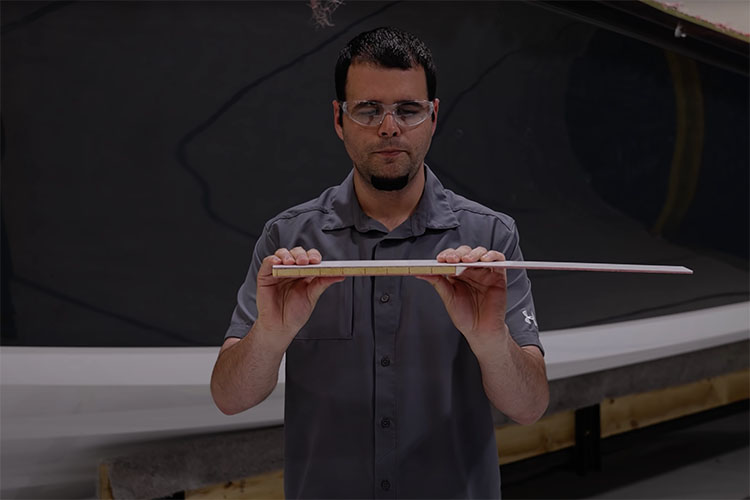

The coring foam offers strength and rigidity at a significantly higher level than fiberglass alone. (The image above shows a demonstration of coring foam’s strength and does not reflect the amount of coring board in any of our boats. It is simply for demonstration purposes.)

One of the most importance pieces of composite material is at the transom. This area feels the stress and weight of the boat’s engines. In this area, we use a no-rot composite material called Coosa board. It will never rot, mold, or mildew.

These materials significantly strengthen the boat while providing better performance and reducing the overall weight. Each boat will have a different level of necessary thickness, but rest assured, our team of qualified engineers and technicians ensure each boat is built correctly and safely so you and your family can enjoy your peace of mind and time while out on the water.

For more information on How Sportsman Boats are made, check out our “Behind the Glass” series: https://www.sportsmanboatsmfg.com/series/1-behind-the-glass-season-1

Information pulled from Building A Boat Hull The Sportsman Way - Sportsman's "Behind The Glass" (Season 1 - Episode 1) and the Sportsman Boats website.